Corrosion management for asset integrity

September 10, 2020 •Corrosion CONTROLLED, Corrosion Management

Corrosion management practices implemented throughout organizations ensure safer, long-lasting protection of assets such as pipelines; increase return on investment (ROI) while decreasing life cycle costs; and preserving the environment.

To further explain the value of corrosion management systems (CMS), how they work, and resources available to help organizations improve their corrosion control programs, three experts in oil and gas pipeline corrosion management spoke with NACE International.

NACE: What tools do you find of value when implementing a corrosion management system throughout an organization?

David Kroon, Aegion Corporation: Support of the CMS throughout the organization from executive management to field operations is most important.

We need to invest in advancing corrosion control technology and systems, but we also need to incorporate these practices in a CMS to maximize the business benefits. This can be accomplished by employing a CMS that is understood and supported by every level of an organization involved in protecting assets.

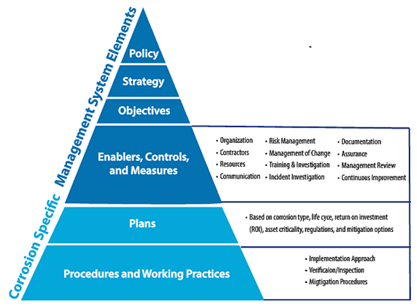

A CMS consists of the following:

• Procedures and working practices

• Plans based upon desired asset life and available mitigation measures

• Enablers, controls, and performance metrics

• Objectives, strategies, and policy

The relationship of these elements is illustrated by the CMS Pyramid below, courtesy of NACE.

I really like this figure since it does such a good job of summarizing everything needed to successfully implement a CMS throughout an organization. Our engineering groups are very good at addressing the bottom two layers of the pyramid focused on procedures and practices, and even planning for regulatory compliance, process improvements, and capital projects.

As we move toward the top of the pyramid, the need for management to be fully engaged is essential for putting in place enablers, controls, and performance measures. Executive management needs to drive the development of CMS objectives, strategy, and policy, and needs to regularly communicate the importance of the CMS to the organization.

Gerry Koch, DNV GL: As stated previously, a culture focused on corrosion management, much like process safety management, must exist within the organization, such that corrosion management is part of the organization’s overall management system. For this to happen there must be buy-in across the organization. First the corrosion professional should broaden his competence with respect to business tools, to include financial decision making, and risk assessment, which is based on expected activity for evaluating corrosion control expenditures. Whenever possible, Life Cycle Costing (LCC) should be considered using such financial tools as Constraint Optimization, and Maintenance Optimization.

Standards provide guidelines to organizations wishing to develop a CMS. NACE Task Group (TG) 564 has developed a “Standard Framework for Establishing Corrosion Management Systems.” It is based on ISO-55000 management standards and a framework developed in NACE’s IMPACT Study, which examines the role of corrosion management in industry and government and establishes best practices.

Michael Ames, Chapman Engineering: Some very good guidance information is available from pipeline regulatory groups such as PHMSA and ASME B31. Another great resource is NACE’s IMPACT PLUS, a robust suite of tools that helps companies measure and manage CMS. “Navigators” are also offered to guide a company through their existing CMS to enhance it and integrate it within all parts of the company.

David Kroon: Yes, IMPACT PLUS is a great resource that provides a CMS framework -- incorporating both technical and business considerations.

Gerry Koch: With the support of the new NACE standard practice, organizations can start to develop their CMS strategies. NACE IMPACT PLUS can then help assess where an organization stands with respect to corrosion management and assist in the development of a roadmap of where they need to go to meet CMS requirements.

NACE: In your experience, how extensively are corrosion management system programs being used in the corrosion industry today? How can their use be more prevalent?

David Kroon: CMS means different things to different people and organizations. In its simplest form, for the regulated pipeline industry, it means nothing more than a program to ensure continuing compliance with PHMSA and EPA corrosion control regulations. This is a short-sighted approach since it robs the organization of all the other benefits. I maintain that a good regulation is good for industry, but we need to work at reaping the benefits. Corrosion engineers regularly speak to management in the terminology of their science and technology. They need to adopt the language of their management and regularly expand the conversation to include discussions of safety, ROI, and LCC. Corrosion threats should be mitigated to a point where the expenditure of resources is measured against the benefits gained. To determine whether a corrosion management investment is appropriate, it can be compared to the potential corrosion consequence through an ROI analysis, which often includes inspection and other maintenance costs.

Michael Ames: I've been involved with the coverage and separation between CMS and pipeline integrity groups that tend to be somewhat at arms-length, when really, they do overlap and can enhance each other more than some have at this time. The significance of this relationship is that one group has a more enhanced corrosion management practice than the other. More attention, in my opinion, is needed to fully integrate these practices in appropriate situations. CMS should be understood and observed in all areas of a company, as they all have their contribution to make to enhance pipeline corrosion management. Consider the impact of budgeting, construction practices, and operation processes—they all impact the ability of a company to manage corrosion, but in many setups, they do not know their involvement or impact. The use of a CMS must be enhanced by having each group understand their part to play and this would usually require meetings to discuss how they interlock with the CMS.

Gerry Koch: The concept of corrosion management may often mean different things to different people and organizations. While over the past few years the understanding of what corrosion management is has increased, there is still a long way to go, since a considerable number of people and organizations regard the concept of corrosion management to be similar to or the same as corrosion engineering. For example, in the pipeline industry corrosion management often means simply meeting regulatory requirements by carrying out cathodic protection and internal corrosion monitoring programs. These programs are considered a cost to the bottom line and corrosion professionals have to constantly justify these costs, while no consideration is given to cost benefits and ROI. These organizations can broaden their view of corrosion management by considering the economic impact of implementing corrosion engineering versus not implementing. By developing a culture of corrosion management buy-in throughout the organization, the full benefit of corrosion management can be achieved.

The corrosion management concepts referenced here are being embraced by some oil and gas companies; which have started to create a corporate culture with buy-in from all levels of management with corrosion being part of the companies’ overall management system

NACE: Any additional comments you may want to add regarding corrosion management?

Michael Ames: Pipeline CMS are the first and best line of protection from corrosion of a pipeline asset. As these programs mature across companies, and the world, there should be better assurance that a pipeline’s neighbor should never have to worry about pipeline safety.

Gerry Koch: The acceptance of the CMS concept may be likened to the acceptance of today’s safety management culture. A few decades ago, safety management merely dealt with occupational safety, which considers relatively high occurrences of slips, trips, and falls, whereas process safety (low likelihood of occurrence and high consequence) received little attention. After a few major process safety-related accidents, a culture developed throughout the oil and gas and refining and petrochemical industries, where safety has become an integral part of the organizations’ management systems. All levels of the organizations now speak the same safety language and have the same goal to improve both occupational and process safety. It is my hope that corrosion will go through the same transition and become part of organizations’ corporate cultures.

David Kroon: We have come a long way. It’s not too long ago when corrosion was viewed as inevitable — pipelines needed to be replaced because they wore out. It is now recognized by the oil and gas pipeline industry that corrosion management saves money and reduces risk. It’s just good business and the right thing to do.

Learn how corrosion management can lead to asset longevity, higher performance, and cost savings for your organization. Learn more about IMPACT PLUS.

Source: Originally appeared on materialsperformance.com by Gretchen A. Jacobson, Managing Editor-in-Chief, Materials Performance.

FREE DOWNLOADS

White Paper: An Action Plan for Reducing Pipeline Failures, Costs with Corrosion in the Water Sector

Special Report: The Future of Corrosion Control, Insights from the Experts

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (4)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (1)

- Ampp Standards (1)

- ampp training (1)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (11)

- Asset maintenance (3)

- Asset Protection (1)

- awards (2)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (2)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (16)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (21)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (16)

- Corrosion Control and Management (23)

- corrosion engineering (1)

- Corrosion Essentials (20)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (10)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (1)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (1)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (2)

- exam preparation (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (2)

- Industry Best Practices (1)

- Industry Standards (1)

- infrastructure (3)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- Intumescent Coatings (1)

- key note speaker (1)

- Machine Learning (1)

- Maintenance (2)

- Maritime Coatings (11)

- Maritime industry (11)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- National Defense Authorization Act (1)

- national security (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- professional certification (2)

- professional development (1)

- Protective Coatings (6)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (2)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Standards (9)

- Standards Committees (1)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (1)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- Workforce development (1)

- WRDA (1)