What regular reporting can do for corrosion management, asset integrity

August 9, 2021 •Corrosion CONTROLLED, Corrosion Management

A regular flow of information and data is needed to make the best and most cost-effective technical, integrity, and financial decisions. This requires a consistent, organized, and transparent reporting system to facilitate existing or upcoming assessments, planning, and corrosion mitigation activities.

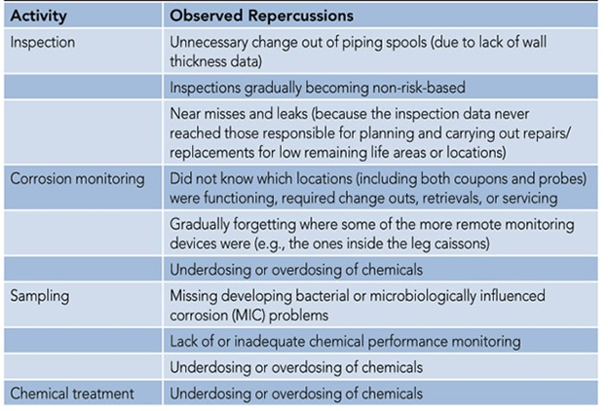

Without this information, integrity repercussions can adversely affect the AIMS, pushing costs unnecessarily high.

Depending on the significance of the corrosion threat associated with an asset, regular reported activities helping to quantify the corrosion rate or mitigate the corrosion may include:

Depending on the significance of the corrosion threat associated with an asset, regular reported activities helping to quantify the corrosion rate or mitigate the corrosion may include:

• Inspection (including intelligent pigging of pipelines)

• Corrosion rate monitoring

• Fluid sampling

• Chemical treatment

• Cleaning

• Repairs and replacements

If corrosion is a major integrity threat, then corrosion reporting should be performed monthly. Otherwise, bimonthly or quarterly corrosion reporting should be adequate.

The findings of these activities must be accurately recorded, reported, and shared among the relevant individuals and disciplines. The regular distribution of results will continually improve knowledge and understanding about the following conditions:

• Integrity condition of the asset

• Specific problem areas

• Performance of various mitigation activities

• Specific integrity shortcomings

• Future corrosion mitigation needs

• Future repair/replacement requirements

• Required resources and budgets

The report itself should be distributed to:

• Asset inspection, process, and operation departments

• Repair/maintenance representative

• Corrosion or integrity managers from both the client and the contractor(s)

• Asset chemist or the representatives of the chemical(s) suppliers

• Asset or installation manager

• Any other person or group involved/interested in the asset’s integrity management

Finally, a solid corrosion report document should incorporate these main components in its structure and content:

• Administrative details

• Integrity-related information and data

• Corrosion key performance indicators (KPIs)

• An asset risk matrix highlighting threats posed to the overall integrity of the asset or its integrity management

• Meeting minutes noting future actions and activities as well as deadlines

The better an asset is known from an integrity or corrosion point of view, the more effective and efficient upcoming technical assessments, plans, treatments, and activities will be. Consequently, with regular reporting, asset integrity management could gradually become more efficient and the pertinent integrity management costs could further be optimized.

Looking for tools to help in implementing a corrosion management system in your organization. Check out IMPACT Plus.

Source: Originally appeared on materialsperformance.com and written by Ali Morshed, corrosion engineering specialist at Saudi Aramco and author of An Introduction to Asset Corrosion Management in the Oil and Gas Industry.

FREE DOWNLOADS

White Paper: An Action Plan for Reducing Pipeline Failures, Costs with Corrosion in the Water Sector

Special Report: The Future of Corrosion Control, Insights from the Experts

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)