Corrosion Prevention Using Real-Time Data in Oil Fields

June 23, 2023 •Corrosion CONTROLLED, Corrosion Essentials, Coatings

|

Revealing the Secrets: Plunge into the Top Three 1. How Can Real-Time Data Revolutionize Corrosion Control in Oil Fields and Extend Asset Lifespan? |

Modern high-resolution corrosion monitors, including electrical resistance probes, are available. These instruments can be installed in key locations and connected to a control room computer. Responsible engineers can observe the real-time corrosion trends from the control room along with other operational parameters. By seeing the corrosion data in real-time, personnel can take immediate mitigation action in situations with high corrosion rates or risks.

Corrosion Inhibitor Injection

Chemical injection is an effective solution to many corrosion problems; however, injection rates below the specified dosage result in inadequate corrosion control and injecting excessive dosages is wasteful and not cost-effective. Monitoring chemical treatments with data loggers obtains real-time data that can help streamline the chemical treatment process. Real-time data are helpful for maintaining the effectiveness and efficiency of the pump skids.

Corrosion inhibitor levels in injection tanks are important. Level control can be computerized and automated. In cases of low inhibitor levels, an alarm can alert the corrosion team so that the chemical supply can be promptly adjusted. This is more efficient than requiring personnel to conduct site visits, note the inhibitor level readings, and replenish the corrosion inhibitor if necessary.

Real-time chemical injection information from data loggers also can help determine the performance of the chemical treatment. Automating this process provides more accurate injection data than manual control during site visits because the inhibitor performance and chemical levels in the tanks are checked only at the time of the visit. Chemical injection quantities are then calculated based on the difference between the levels measured during the site visits. Automation is particularly useful for remote sites. By implementing automation, it is possible to continuously monitor the corrosion inhibitor injection and performance, make necessary adjustments when needed, and thereby minimize the corrosion of assets.

Monitoring Inhibitors in Pipelines

Identifying the corrosivity of fluid flowing in a pipeline or system is essential when adjusting the formulation of the inhibitors. Off-the-shelf inhibitor formulations may not always work. It is better to have tailor-made inhibitors that suit the specific conditions exactly.

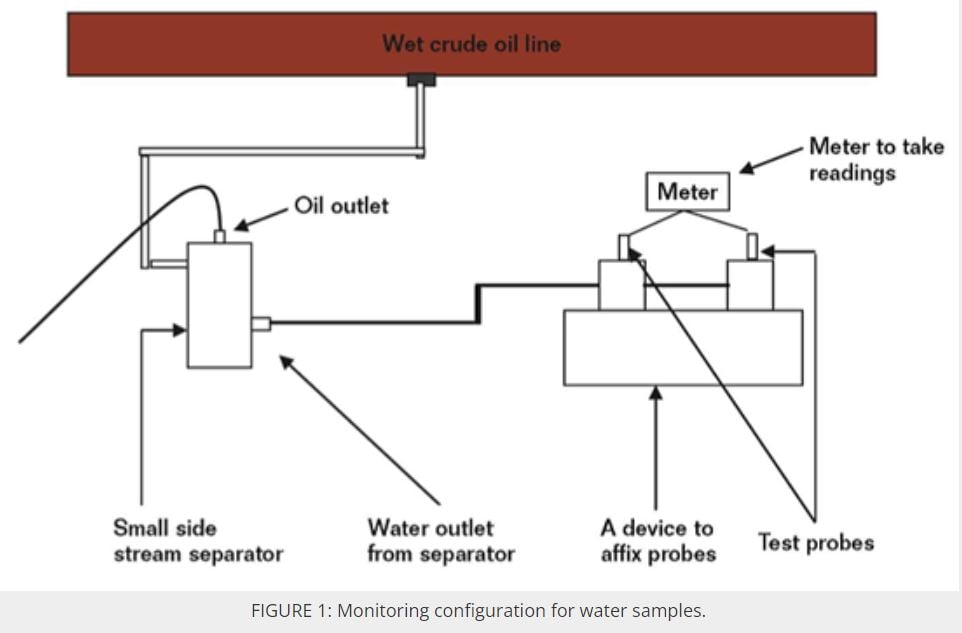

The corrosivity of free water in oil lines can be tested by following the side stream technique (Figure 1). This can be carried out from a sampling point at the 6 o’clock position in the circumference of a wet crude oil pipeline. Tubing is connected from this sampling point to a small side stream separator that will yield oil-free water for testing. The water outlet of the separator is connected to a device with linear polarization resistance (LPR) probes affixed to it. By monitoring the LPR meter or using electrochemical impedance spectroscopy techniques, corrosivity can be checked.

This side stream equipment also can be used to inject and test inhibitor formulations. Preparing an inhibitor in a laboratory with collected samples may involve numerous, complex factors. There can be problems associated with dissolved oxygen (DO) ingress and liberation of dissolved gases from samples collected in containers and transported to a laboratory. Similarly, establishing system pressure, temperature, and other conditions in a corrosion testing laboratory is often very difficult.

Using side stream equipment for online sampling can simplify this work because the fluid exposed to the test electrodes is exactly the same as the pipeline fluid. Also, the system pressure, temperature, and other conditions remain consistent. Water from the side stream equipment also can be used for testing dissolved gases such as carbon dioxide (CO2), hydrogen sulfide (H2S), and DO. Additionally, chemical constituents in the water, such as dissolved iron and total iron, can be checked with the help of appropriate standardized field test kits.

Normally, corrosion coupons are available for placement in the 6 o’clock position within pipelines. Coupon holders are also available with sample collection systems. Fluid can flow through the coupon holder to the outlet that is connected to the side stream equipment. Considerable care, however, must be exercised in unscrewing the coupon holder to allow fluid flow while avoiding holder displacement under high pressure. It is also important to confirm that the fluid flow is not blocked by particles that could impede the collection of side stream samples. This method gives real-time data of fluid corrosivity and provides data that are also representative of actual field conditions. In side stream equipment, two probes can be connected in a series to check their accuracy.

Conclusions

A dynamic approach to corrosion monitoring is essential. Acquiring and analyzing real-time data greatly facilitates corrosion prevention. Traditional methods concentrate on detecting and evaluating corrosion after it has occurred. Corrosion monitoring techniques should concentrate on collecting real-time data to identify corrosion risks in time to prevent significant losses and failures.

This article by Tata L.N. Murthy was originally published online for Materials Performance Magazine. Republished with permission.

Check out AMPP's Oil and Gas Production articles, related courses, and certifications. Keep reading to find out more.

More Industry Resources

Elevate Your Skills in Corrosion Control with AMPP

Are you involved in the refining industry? AMPP's Corrosion Controlled Blog presents an invaluable opportunity through the Refining Corrosion Technologist certification course. This course provides insight into corrosion’s impact on refineries and explores techniques for effective corrosion control, including material selection, design, and maintenance.

Harness your potential by gaining specialized knowledge in corrosion control, and contribute to the safety and efficiency of refinery operations. Join us and take the next step in your career. Sign Up Now.

Stay Informed with the AMPPlify Newsletter:

.png?width=1500&height=750&name=AMPPlify%20Template%20Header%202023%20(2).png)

The AMPPlify Update is a resourceful monthly newsletter for those interested in materials protection and performance. In the current issue, you will find information on honoring women in engineering, details on chapter elections, updates on standards, and insights into technical content. Additionally, it covers job opportunities in the field and highlights from AMPP community events. The AMPPlify Newsletter is an essential read for staying connected and informed. Sign up today!

Internal Monitoring Solutions for Integrity Management

In this podcast, Roland Anderson, business development director at monitoring solutions company Axess Corrosion, explains how the group’s patented Janus range works to reduce risk.

With integrated alarm systems available to measure process corrosion, erosion, wall thickness, and more, Anderson elaborates on feedback from the field; trends in the marketplace; unique needs for oil and gas clients; and much more.

Respiratory Compliance Best Practices

In this webcast, learn how vital respiratory protection is for those working with coatings applications. Dive into the risks posed by hazardous chemicals like volatile organic compounds (VOCs) and isocyanates, and gain insights on selecting, using, and maintaining protective gear. By adopting these practices, employers can ensure their workforce's health and mitigate risks. Join us for essential knowledge on respiratory safety in coatings applications.

Available On-Demand | Duration: 1 Hour 2 Minutes | Earn PDHs | FREE

You Talk...We Listen

Tell us how we are doing and what you would like to see in future blog posts.

We want to hear from you in this quick two-minute AMPP Poll.

Unlock success at AMPP! Become an AMPP Member and tap into a treasure trove of perks - from certification renewal discounts, exclusive courses, and coveted AMPP products to enriching networking events and invaluable industry insights. With membership levels tailored to your needs, your key to growth is just a click away. Join AMPP Today! 🚀

Unlock success at AMPP! Become an AMPP Member and tap into a treasure trove of perks - from certification renewal discounts, exclusive courses, and coveted AMPP products to enriching networking events and invaluable industry insights. With membership levels tailored to your needs, your key to growth is just a click away. Join AMPP Today! 🚀

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)

.png?width=722&height=120&name=CROSS%20PROMO%20BANNER%20TEMPLATE%20%20(1).png)