Corrosion Basics - Water Constituents

March 10, 2023 •Corrosion CONTROLLED, Corrosion Essentials, Coatings

The concentrations of various substances in water in dissolved, colloidal, or suspended form are typically low but may vary considerably, depending on the components and usage. For example, hardness values of up to 400 parts per million (ppm) of calcium carbonate (CaCO3) is sometimes tolerated in public supplies of potable water, whereas 1 ppm of dissolved iron would be unacceptable. In treated water for high-pressure boilers or where radiation effects are important, as in some nuclear reactors, very small concentrations of impurities can be significant, and these are measured in very small units such as parts per billion. Water analysis for drinking water supplies is concerned mainly with toxins, pollutants, and bacteriological tests. For industrial supplies, a mineral analysis is of more interest. The important constituents can be classified as follows:

• Dissolved gases (oxygen, nitrogen, carbon dioxide [CO2], ammonia [NH3], and sulfurous gases)

• Mineral constituents, including hardness (principally calcium and magnesium) salts, sodium salts (chloride, sulfate, nitrate, bicarbonate, etc.), salts of heavy metals, and silica

• Organic matter, including that of both animal and vegetable origin, oil, trade waste (including agricultural) constituents, and synthetic detergents

• Microbiological forms, including various types of algae and slime-forming bacteria

The pH of natural waters is rarely outside the fairly narrow range of 4.5 to 8.5. Higher values, at which corrosion of steel may be suppressed by passivation of the surface, and lower values, at which gaseous hydrogen evolution occurs, are not often found in natural waters. Copper is affected to a marked extent by pH value. In acidic waters, slight corrosion occurs; and the small amount of copper in solution causes green staining of fabrics and sanitary ware. In addition, redeposition of copper on aluminum or galvanized surfaces sets up dissimilar metal corrosion cells, resulting in severe pitting of the more active metals.

From a corrosion standpoint, the most significant contaminant is dissolved oxygen (DO) from ambient air. Oxygen is a cathodic depolarizer that reacts with and removes the hydrogen ion film from the cathode surface during electrochemical corrosion, thereby permitting corrosion attack to continue. In a closed vessel, corrosion rates increase with temperature, hence the importance of removing DO from hot water systems and boilers. In a range of about pH 5 to 9, the corrosion rates of steel and most other metals can be expressed in terms of the amount of DO present (e.g., μm/y per mL of DO per liter of water). At about pH 4.5, acid corrosion is initiated, overwhelming the oxygen control. At about pH 9.5 and above, deposition of insoluble ferric hydroxide [Fe(OH)3] tends to stifle the corrosion attack.

Other constituents that contribute to corrosion are chlorides, CO2, calcium, and sulfides or NH3 from industrial or natural sources. Of course, many other manmade contaminants can be found in local water resources where industries are permitted to discharge their waste products. As with other chemical reactions, corrosion increases with elevated temperature, unless stifled by insoluble scales, the removal of corrosive gases, or the addition of corrosion inhibitors.

Scales precipitated uniformly onto metal surfaces can provide excellent protection of the substrate but can accentuate pitting at pores, cracks, or other voids in the film. If the film attains any significant thickness, the loss of heat transfer through the metal and deposited scale can be a problem in certain applications. Thus, the development and control of scale formation on metal surfaces is an important consideration when using metals in waters.

This article is adapted by MP Technical Editor Norm Moriber from Corrosion Basics—An Introduction, Second Edition, Pierre R. Roberge, ed. (Houston, TX: NACE International, 2006), pp. 514-516.

This article by Pierre R. Roberge was originally published online for Materials Performance Magazine. Photos courtesy of Sherwin Alumina. Republished with permission.

Check out AMPP's Corrosion in the Water and Wastewater Industry articles, related courses and certifications. Keep reading to find out more.

More Industry Resources

Introducing the Forefront Innovation Series

(Formerly the Corrosion Technical Series)

Filled with the latest insights and technical developments, AMPP’s new web-based series brings together subject matter experts from various industries and professional backgrounds to discuss new and emerging topics focused on materials protection and performance. Utilizing best practices, case studies, and lessons learned, these engaging sessions will shed light on challenges faced by different industries.

Filled with the latest insights and technical developments, AMPP’s new web-based series brings together subject matter experts from various industries and professional backgrounds to discuss new and emerging topics focused on materials protection and performance. Utilizing best practices, case studies, and lessons learned, these engaging sessions will shed light on challenges faced by different industries.

Upcoming event:

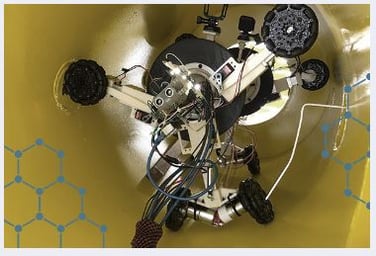

Drone and Robotics Equipment: What Can This Technology Do? March 14-15, 2023

Understanding the technology and the standardization of drone usage is still evolving. While drones and robotics are often used for inspection, we will also discuss how they are used in other applications, such as surface preparation and the application of materials. Event details | Register | 6 PDH

The AMPP Latin American Chapters are putting together several activities – area and global news update, upcoming courses and events in the area - for the benefit of the news subscribers. We invite you to stay informed, participate and engage with other professionals to continue growing your technical or professional field.

The AMPP Latin American Chapters are putting together several activities – area and global news update, upcoming courses and events in the area - for the benefit of the news subscribers. We invite you to stay informed, participate and engage with other professionals to continue growing your technical or professional field.

Webinars are also being scheduled frequently by Argentina and Brazil Chapters. Subscribe to be notified when a new article is published!

EAPA News

EAPA news features global coatings and corrosion trends and activities specific to East Asia and the Pacific, as well as general AMPP news. Content is often submitted by local AMPP staff and members. Continue to stay up to date with the latest news - instead of quarterly updates, EAPA news will be updated more frequently with our improved online experience. Subscribe now!

Featured Webcast: Tools and Techniques for Managing Corrosion at Water and Wastewater Utilities | Available On-Demand | Duration: 1 hour, 1 minute

The first episode of the Flint Phenomenon series discusses the water crisis in Flint, Michigan, including the causes of lead release in the drinking water and how the situation was handled. It includes discussion on the difficulty in identifying and replacing lead pipe in Flint and throughout the United States. The episode includes discussion with panelists Marc Edwards, who led the team that collected the water samples in Flint, and Darren Lytle with the Environmental Protection Agency.

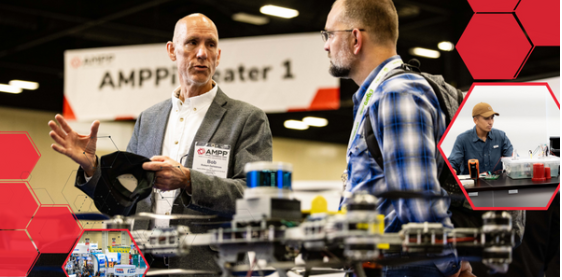

Thank you to everyone who participated in the AMPP Annual Conference + Expo 2022 surveys and focus groups last year. In response to your feedback, we made several improvements to enhance the overall conference experience for this year. Check out the AMPP Conference + Expo Fact Sheet for a sneak peek at what’s in store next month. Thanks to your feedback, we’ve made great progress, but there is always room for improvement. Be on the lookout for the post-conference survey so we can make 2024 even better!

Thank you to everyone who participated in the AMPP Annual Conference + Expo 2022 surveys and focus groups last year. In response to your feedback, we made several improvements to enhance the overall conference experience for this year. Check out the AMPP Conference + Expo Fact Sheet for a sneak peek at what’s in store next month. Thanks to your feedback, we’ve made great progress, but there is always room for improvement. Be on the lookout for the post-conference survey so we can make 2024 even better!

Register online by March 16th!

Gain key industry insights from over 600 hours of programming and hands-on training, including peer-reviewed symposia, forums, workshops, standards and administrative meetings, informational exchanges, student poster sessions, and networking opportunities..png?width=722&height=120&name=CROSS%20PROMO%20BANNER%20TEMPLATE%20%20(1).png)

NACE and SSPC are now AMPP, The Association for Materials Protection and Performance. Join AMPP Today!

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)