UAVs Capable of Inspecting Ship Tanks for Signs of Corrosion

April 14, 2023 •Corrosion CONTROLLED, Corrosion Essentials, Coatings

The first production survey using an unmanned aerial vehicle (UAV) to assist surveyors was recently completed by classification society DNV GL (Høvik, Norway). The survey, which took place on the MV Apollo, a chemical tanker owned by Carl Büttner Shipmanagement GmbH in Bremerhaven, Germany, was completed in two and a half days by two DNV GL surveyors who used a UAV, also known as a drone, to help assess 14 cargo tanks.

The first production survey using an unmanned aerial vehicle (UAV) to assist surveyors was recently completed by classification society DNV GL (Høvik, Norway). The survey, which took place on the MV Apollo, a chemical tanker owned by Carl Büttner Shipmanagement GmbH in Bremerhaven, Germany, was completed in two and a half days by two DNV GL surveyors who used a UAV, also known as a drone, to help assess 14 cargo tanks.

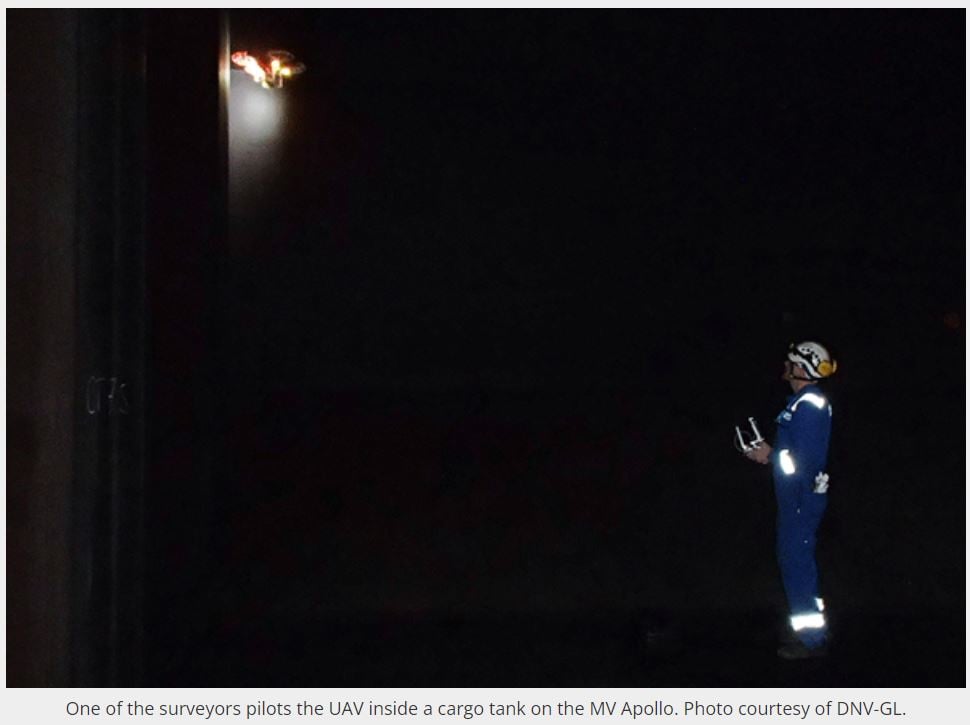

Inspecting ship tanks and holds can be a costly, time consuming, and potentially dangerous operation. Assessing structures such as piping, access points, equipment, and safety systems for coating condition, corrosion, and damage needs to be done on a regular basis. The sheer size of today’s vessels, however, requires staging, rafting, and climbing for surveyors to access areas slated for inspection and make their observations. By using UAV technology, surveyor safety is improved and survey times and staging costs associated with visual condition checks of remote structural components can be significantly reduced. For the MV Apollo survey, eliminating the staging construction realized a time savings of two to three days for all 14 tanks, with total costs savings estimated to be somewhere between €14,000 to €28,000, or €1,000 to €2,000 per scaffold per tank. With a UAV, a complete close-up survey of a cargo tank measuring ~20 by 30 by 15 m takes about two to three hours.

To ensure that the required safety and quality levels are reached, DNV GL is in the process of developing an in-house guideline to cover drone-assisted surveys performed by its surveyors.

To ensure that the required safety and quality levels are reached, DNV GL is in the process of developing an in-house guideline to cover drone-assisted surveys performed by its surveyors.

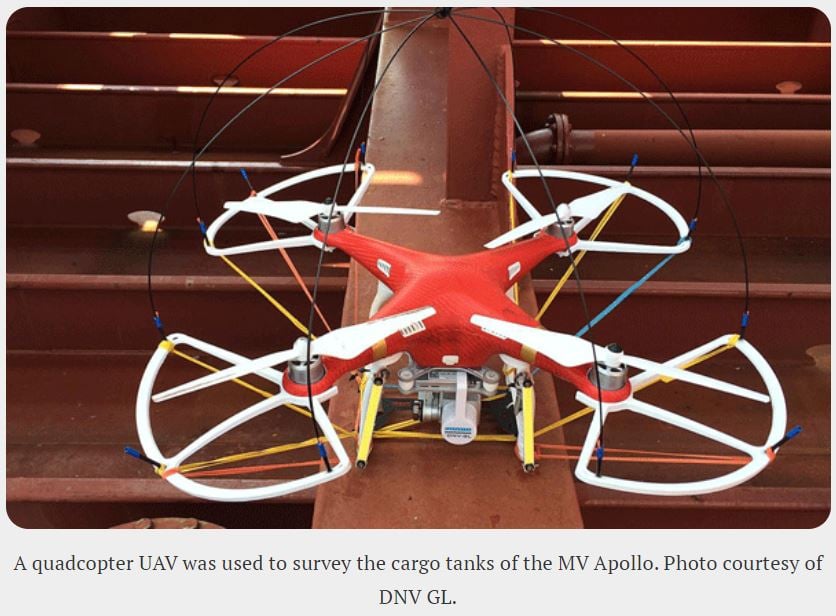

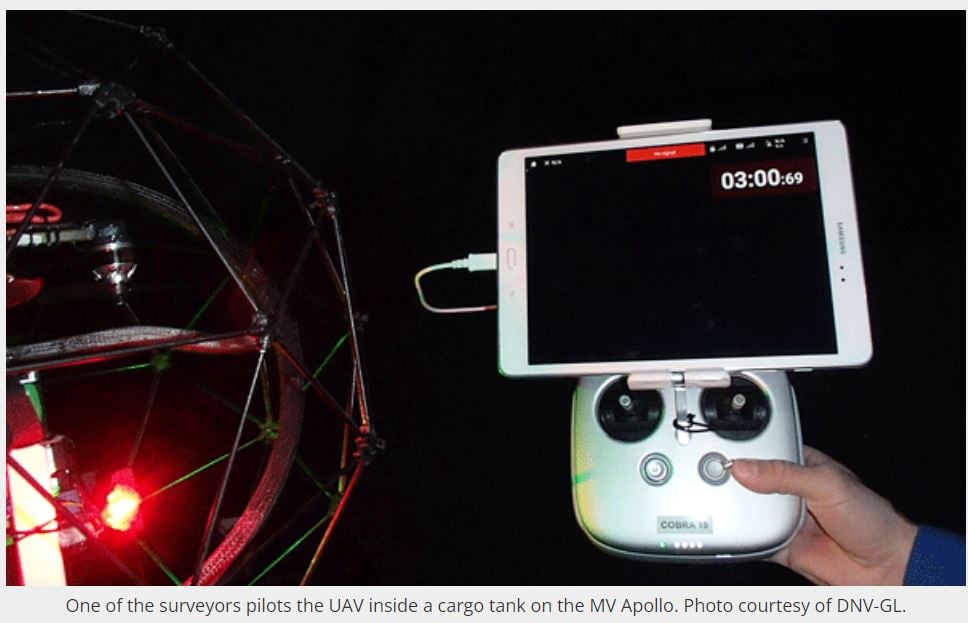

To visually evaluate the MV Apollo’s structural components, the two surveyors used a UAV equipped with a DJI Phantom 3 camera that streamed live video to a tablet. One surveyor piloted the UAV, while the other focused on the real-time video feed. Additional lights were installed on the UAV, and its propellers were fitted with protective gear. Because the additional lights reduced the UAV’s battery life, the survey team had six to seven charged batteries available and landed the UAV approximately every 15 min to furnish it with a fresh battery.

The images generated by the UAV captured a level of detail equivalent to that of the human eye from a distance of 1.5 m, as specified in DNV-GL/IACS requirements. This means the results can be used in official surveys, DNV GL says. The video stream was also recorded for review and documentation purposes.

“The advantage of using a drone over conventional staging inside the tank is absolutely clear,” says Jochen Huhn, marine superintendent and chief security officer with Carl Büttner Shipmanagement GmbH. “Eliminating the risk of damage to the coating from staging means the drone survey is worth it, even before we factor in the time saved by this method. We were also all very impressed by the quality of the video and the details the drone was able to obtain in the inspection. We would certainly be interested in using this method more in the future and I am interested to see how the technology develops over the next few years.”

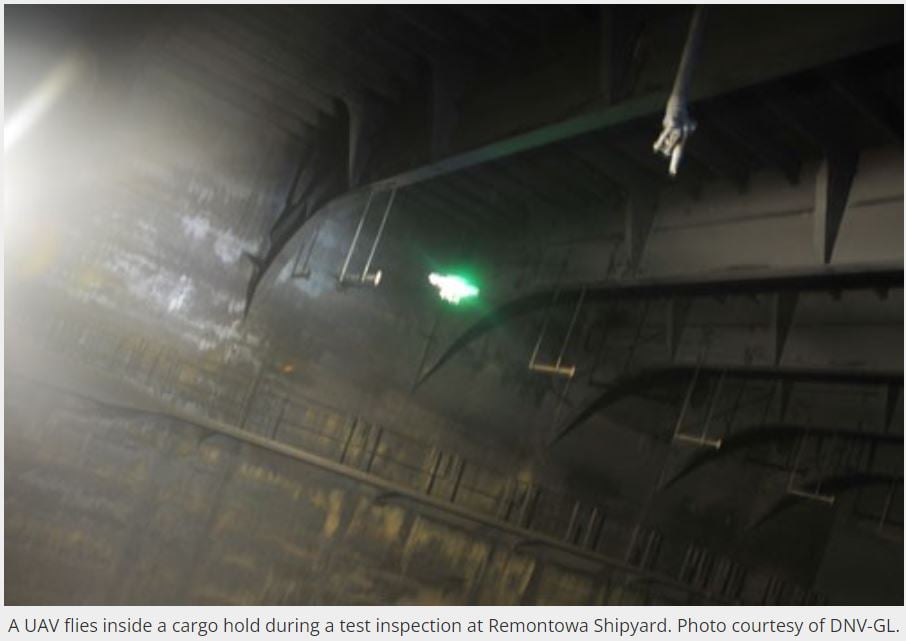

DNV GL has tested the use of UAVs to conduct surveys inside ship tanks and completed several tests utilizing UAVs to inspect cargo tanks and holds in a large oil tanker, a chemical tanker, and a bulk carrier, in both Europe and China. In December 2015, several tests using UAVs to support the hull survey of two vessels at the Remontowa shipyard in Gdansk, Poland were completed by a DNV GL classification team.

DNV GL has tested the use of UAVs to conduct surveys inside ship tanks and completed several tests utilizing UAVs to inspect cargo tanks and holds in a large oil tanker, a chemical tanker, and a bulk carrier, in both Europe and China. In December 2015, several tests using UAVs to support the hull survey of two vessels at the Remontowa shipyard in Gdansk, Poland were completed by a DNV GL classification team.

“We have been looking at ways we could help our customers by accelerating the survey process,” says Cezary Galinski, manager of the DNV GL–Maritime classification flying squad based in Gdansk. “Camera-equipped drones are now much more widely available and affordable, and by using them for a first screening we can identify areas that require closer inspection quickly and without extensive staging, which can be both costly and time-consuming.”

In the event that any damage is detected, a traditional close-up survey of the damaged area may still be required. Galinski noted that the team used a modified, off-the-shelf UAV for its tests. Because there are no commercially available UAVs currently certified as explosion-proof, the surveyors performed a risk assessment before the inspection and also ensured the cargo tank was gas-free and certified for safe entry before the drone operation started.

The next step, Galinski says, is to develop a more advanced, tailor-made UAV, and the group is working with a supplier to build a custom vehicle for future use. One issue to be addressed is size—a UAV design is needed that can fit through a ship’s standard-size manhole, which can be as small as 400 by 600 mm, and be easily packed by a single surveyor for transport and deployment. Additional design improvements desired by the group include increased battery endurance, a better camera, higher-quality lighting, and enhanced flight stability through the use of ultrasonic and laser-based devices.

Going forward, it may be possible to conduct inspections using fully autonomous UAVs. DNV GL has three-dimensional (3D) models of many of its ships, so a 3D model could be loaded into a UAV’s memory, Galinski explains. The UAV could then orientate itself inside the tank and follow a predefined route, and stop inside the compartment to take a photo or video at points of interest. While the autopilot would handle the UAV’s flight path, the operator could manipulate the camera and lights to assess the structures and document findings.

Using a UAV with an advanced inspection technology such as DNV GL’s IRIS system—a camera and tracking system for inspectors or surveyors working inside tanks that can automatically associate onboard photos taken by the surveyor with the corresponding points inside a 3D model of the vessel’s structure—could be the first step toward an automated survey process. This would include using a UAV to conduct the initial survey, and then running the generated images through an algorithm to determine the hull condition.

At some stage it may be feasible to have a UAV with its own scanning capabilities. The vehicle could be launched into a space, make a scan, create a 3D map, and then carry out an independent survey of the space. “But we are still a fair way away from this,” Galinski says.

Currently, the challenge with autonomous flight in a cargo tank is guidance. UAVs are equipped with magnetic compasses and gyroscopes so they can be guided by a global positioning system (GPS); however, GPS does not work inside a cargo tank. This creates a challenge for a UAV to maintain a stable position inside a tank without any operator input. “We have been testing other solutions such as barometric sensors, but they did not work as well as we hoped because the drone creates a draught as it approaches the deckhead, which means the pressure isn’t stable and the drone thinks it is lower than it actually is,” says Galinski. DNV GL is currently working on this issue, but it is still a little further down the development pipeline.

Currently, the challenge with autonomous flight in a cargo tank is guidance. UAVs are equipped with magnetic compasses and gyroscopes so they can be guided by a global positioning system (GPS); however, GPS does not work inside a cargo tank. This creates a challenge for a UAV to maintain a stable position inside a tank without any operator input. “We have been testing other solutions such as barometric sensors, but they did not work as well as we hoped because the drone creates a draught as it approaches the deckhead, which means the pressure isn’t stable and the drone thinks it is lower than it actually is,” says Galinski. DNV GL is currently working on this issue, but it is still a little further down the development pipeline.

In the meantime, a special guideline for performing drone-based surveys is being developed, which could lead to remote or autonomous inspections being carried out as part of a survey plan.

DNV GL is also looking into utilizing UAVs and other devices to inspect topside and external structures, as well as internal tanks, on mobile offshore units (MOUs)—buoyant structures engaged in offshore operations, such as drilling, production, storage, and support functions, that can be relocated without major dismantling or modification. Another ongoing project is to establish a certification service that qualifies external UAV operators to perform inspection work on classed MOUs.

“Over the next few years we will continue to work on expanding the ways the drones can be used and the number of stations where we can offer this service. This is a very promising beginning and one that is already showing a significant benefit in terms of time and costs saved.” says Knut Ørbeck-Nilssen, CEO of DNV GL–Maritime.

Source: DNV GL–Maritime, dnvgl.com. Contact Simon Adams, DNV GL–Maritime—E-mail: simon.adams@dnvgl.com.

This article by Kathy Riggs Larsen was originally published online for Materials Performance Magazine. Photos courtesy of DNV-GL. Republished with permission.

Check out AMPP's Maritime Industry articles, related courses and certifications. Keep reading to find out more.

More Industry Resources

Education and Certifications

The Offshore Corrosion Assessment Training (O-CAT Technician)

The O-CAT Technician Certification addresses the elements of in-service inspection and maintenance planning for fixed offshore structures.

The course focuses on the inspection, evaluation, and maintenance planning for fixed offshore structures. Special attention is given to corrosion protection systems commonly used in offshore facilities. The Minerals Management Services (MMS) A-B-C facility evaluation grading system requirements for Level 1 Inspection Reporting are also covered.

Shipboard Corrosion Assessment Technician (S-CAT)

Shipboard Corrosion Assessment Technician (S-CAT)

The Shipboard Corrosion Assessment Training Technician Certification encompasses a knowledge of coatings, corrosion, and corrosion control assessing the condition of tanks and other military ship structures, to help maintain full operational status.

The Shipboard Corrosion Assessment Training course provides a foundation of coatings, corrosion, and corrosion control knowledge related to determining the condition of ships, tanks, and related waterborne structures. It provides a knowledge base of required actions to effectively maintain the structure in fully operational status. The course equips the naval assessor with practical guidelines for surveying and evaluating the condition of the protective coating system on specific areas of U.S. Navy vessels. Classroom instruction is comprised of lectures, discussions, and assessments.

Featured Webcast: The Economies of Corrosion Management in the Maritime Industry | Available On-Demand | Duration: 40 Minutes

Incorporating corrosion mitigating measures into planning, design, construction, and operations can be seen as an unreasonable cost given the "over the horizon" nature of the risk. Therefore, often minimum attention is given up front to the risk of corrosion compared to other more immediate hazards. In this webcast, learn why you should avoid waiting until the problem becomes visible, and stop "chasing rust."

AMPP Technical Exchange on Ship Biofouling - A Success Story

This podcast episode features a roundtable discussion with Elisabeth Charmley, Naval Architect for one of the world's largest ship managers; Johnny Eliasson, Hull and Coatings Engineer at Chevron Shipping; and Buddy Reams, Captain USCG (retired), Chief Technical/Maritime Officer of the Association for Materials Protection and Performance (AMPP). All three are members of TEG532x, which is a Technical Exchange Group (TEG) that remains very active in areas related to ship hull fouling, antifouling methods, aquatic invasive species, and other biofouling-related interests of the commercial shipping community.

There’s Still Time to Register For On-Demand Access!

Couldn't attend the AMPP Annual Conference + Expo this year? Did you miss out on any exciting sessions? We've got you covered! Get on-demand access today before time runs out!

World Corrosion Awareness Day - April 24, 2023

To remind us and others that ‘rust never sleeps,’ we will recognize World Corrosion Awareness Day on April 24. International corrosion associations address corrosion prevention and control measures on this day annually and promote sustainable development practices.

AMPP plans to recognize this important day to further its mission of “advancing materials performance to protect society, assets, and the environment.” With help from our international member community, AMPP chapters from around the world, and AMPP staff, we will flood social media with content about the impact corrosion plays in society, careers in corrosion, and corrosion prevention.

You Talk...We Listen

Tell us how we are doing and what you would like to see in future AMPPlify Updates. We want to hear from you in this quick two-minute AMPP poll.

NACE and SSPC are now AMPP, The Association for Materials Protection and Performance. Join AMPP Today!

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)

.png?width=722&height=120&name=CROSS%20PROMO%20BANNER%20TEMPLATE%20%20(1).png)