Nanotechnology in the Coatings Industry

October 21, 2021 •Corrosion CONTROLLED, Corrosion Essentials, Coatings

What was once considered a humble coat of paint has become a rapidly expanding global coatings market, with highly specialized applications that serve to reduce corrosion costs in nearly every industrial environment. Today, one of the fastest-growing trends in the coatings industry is nanotechnology.

Nanotechnology is considered to be the branch of technology that deals with dimensions and tolerances of less than 100 nanometers, especially the manipulation of individual atoms and molecules. In coatings, nanocomposites and nanostructures have applications that make surfaces scratch-resistant, waterproof, heat resistant, or self-healing. Hospitals are using nanocoatings to maintain sterile surfaces, while aerospace and automotive manufacturers have innovated applications for nanotechnology that makes materials stronger and more lightweight.

In the past decade, tens of thousands of patents have been issued for nanotechnology in the coatings industry alone. Tiny metallic or ceramic particles can be added to existing paint formulations to transform its properties, including corrosion resistance. The minute size of these particles ranges from 10 to 70 nanometers. For example, as explained in a report by IHS Markit, “at 2 nanometers, the conductivity of metal particles changes and at 20 nanometerst., the transparency of ceramic particles changes. At 20 nanometers, particles of gold turn red and their plasticity disappears.”

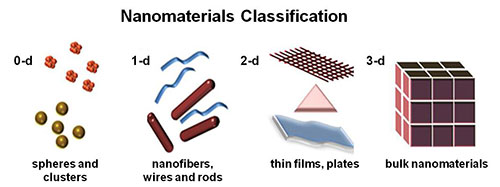

According to NACE's Nanotechnology and Corrosion Technology Exchange Group*, nanomaterials are classified as 0-, 1-, 2- and 3-dimensional structures where at least one dimension is less than 100 nm. The figure presents this classification and provides examples of each form of nanostructures, including clusters/spheres, nano wires, polymers, thin films and bulk specimens. Since the surface properties of nanomaterials dominate bulk, by controlling the surface/volume aspect (particle radius, film thickness or grain size), it is possible to develop materials whose physical properties will be related to surface.

This new technology is still expensive and thus limited to highly specialized applications, but new research is highlighting ways to decrease the cost of manufacturing and applying nanocoatings. In 2016, a team of Australian researchers developed a new protective coating with a range of potential applications, such as preventing ice from forming on aircraft or protecting boat hulls from corrosion. Furthermore, they created two methods for creating this material, both of which are cheaper and easier than current manufacturing processes.

NACE's Technology Exchange Group members are monitoring and analyzing new developments in nanotechnology. The group was established in 2013 to discuss and promote the scope and implementation of this technology in various fields including military, oil and gas, semiconductors, and more.

NACE members with expertise in nanotechnology consider the study and application of nanomaterials in corrosion control still in their infancy, and an understanding of the relationships between their properties and their materials engineering on a molecular level seems to be key to the realization of nanomaterials’ full potential in corrosion control.

* NACE International and SSPC: The Society for Protective Coatings have merged to form AMPP, The Association for Materials Protection and Performance.

For all things coatings, don't miss the Coatings+ conference presented by AMPP, scheduled for December 13-16, 2021 in Phoenix, AZ. Stay current with the latest protective coating tips, techniques, and technologies with a a free subscription to CoatingsPro Magazine.

FREE DOWNLOADS

White Paper: An Action Plan for Reducing Pipeline Failures, Costs with Corrosion in the Water Sector

Special Report: The Future of Corrosion Control, Insights from the Experts

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)