Risk-based inspections help to manage and pre-empt asset failures due to corrosion

July 20, 2020 •Corrosion CONTROLLED, Corrosion Management

Fully implemented corrosion management should address inspection and failure risk assessment (FRA), with the FRA process including an inspection scope that is fully risk-based. While one of the most efficient types of inspections, to render it fully risk-based – with greater corrosion failure pre-emption capabilities – more input data types during the probability calculations of risk-based inspections (RBI) must be used.

Why inspect?

There are many reasons for inspecting industrial or other assets. Inspections are also carried out to:

• Meet legal safety requirements

• Determine or estimate the deterioration rate and then the remaining life of the equipment

• Identify equipment faults, defects, and missing parts

• Identify the acting deterioration mechanism(s)

• Identify anomalies (inspected items, where the inspected parameter, such as thickness and length, is outside an accepted defined limit)

• Determine equipment integrity, functioning, and efficiency

• Detect leaks

Different inspection types

There are four types of inspection with the distinguishing factor among them being the criterion used to determine and create the inspection scope.

1. Time-based

Certain points or locations are selected, often shortly after the asset’s commissioning phase, and are then inspected at fixed time intervals throughout the operation phase. Ideally, as the asset ages and corrosion-related issues and leaks increase, both the scope (i.e., the selected locations) and the time interval should be reviewed and revised accordingly to enable the inspection team to identify those locations that might become a corrosion leak in the foreseeable future.

2. Condition-based

Here, the criterion used for determining both the inspection location and the inspection interval is the condition of the equipment or in other words, the associated deterioration rate, hence, the estimated remaining life of the pertinent equipment. Such criterion is also referred to as rule-based inspection, where the inspection interval is a fraction of, often equal to or less than the half of, the remaining life of the associated equipment.

3. Consequence-based

In this type of inspection, the consequence of failure is the main criterion for determining the inspection scope — the higher service classes (i.e., the more flammable and poisonous fluids, if applicable) require more extensive inspections at shorter time intervals.

4. Risk-based

In this category, the concept of risk (i.e., the product of probability and consequence, where both are associated with the phenomenon of failure due to corrosion) is the main criterion for determining the inspection scope. To determine an inspection scope that is risk-based, probability of equipment failure is dependent on: incumbent corrosion rates and number of past corrosion failures and repairs; the consequence of their failure, that is dependent on incumbent process conditions and the liquid’s flammability and toxicity, again, if applicable.

If adequate input data are used to create a fully RBI scope, this type of inspection enhances the corrosion failure pre-emption capability of the associated inspection program significantly and improves asset uptime and operability considerably.

Based on numerous site visits and integrity audits, RBI has been found to be the most efficient inspection type among the four inspection categories; in particular, in pre-empting corrosion failures.

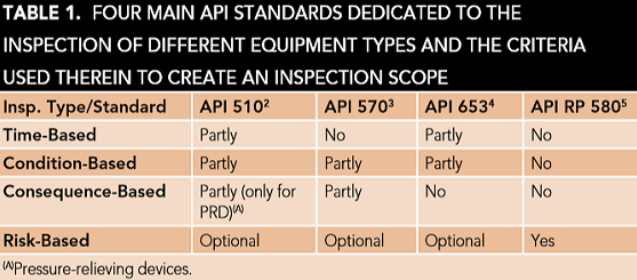

Table 1 provides a list of the four API standards that provide guidelines for the inspection of various equipment types. This table categorizes the listed standards based on the criteria used therein to create the inspection scope. As illustrated by Table 1, such standards mostly use a combination of several criteria to create or determine the inspection scope. While API standards mostly focus on the hydrocarbon industry, similar standards exist that provide similar risk guidance for the non-hydrocarbon industries.

The relationship between corrosion management and RBI

Corrosion management (CM) and RBI are neither synonymous, nor identical processes. In reality, the former is a process, while the latter is a product. Appreciating such a difference is crucial, since some companies that have carried out RBI falsely and mistakenly claim that they have implemented the CM process across their asset(s). Such belief is only partially true since an RBI scope is only one of the many products or outputs of the CM process implementation.

To clarify their relationship, the CM process, once fully implemented, should address and satisfy certain non-corrosion engineering requirements, including inspection, corrosion monitoring, management, and failure risk assessment (FRA). To address the latter requirements (i.e., FRA requirements) means to carry out the FRA process as part of the overall CM implementation process, whose main product or output is an inspection scope that is fully risk-based. Consequently, when discussing CM and RBI, the latter should be considered as one of the main outputs of the former.

Shortcomings with audited RBI systems

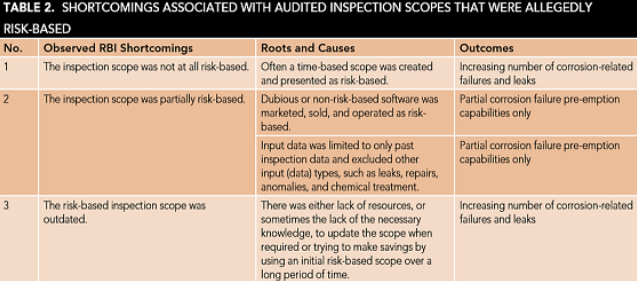

Numerous site visits and integrity audits have revealed that, unfortunately, a considerable portion of the claimed RBIs conducted were not actually fully or even partially risk-based, efficient, and successful, nor did they even produce reliable inspection results. One of the main signs of such failures was the increasing number of corrosion leaks and equipment failures that had not been identified in time by the alleged RBIs carried out. Table 2 summarizes such observed RBI shortcomings, along with the relevant roots and the resultant outcomes.

In the majority of assets visited, an RBI scope is often created using merely the past inspection data, often in the form of wall thickness data. In such cases, other valuable input data types such as: leaks, repairs, anomalies, chemical treatment, and corrosion monitoring are excluded or simply ignored. Therefore, the created inspection scope is only partially risk-based. That is, because such input data also contribute to the determination of the probability component of the incumbent risk value or magnitude, where risk is the product of probability and consequence.

In the absence of such input data, the magnitude of the determined probability is not as accurate compared to when they are included in the risk calculations. Consequently, the resultant risk value, in other words the locations to be inspected, and accordingly, the associated inspection intervals, are not accurate. The outcome is a partial RBI scope with a weakened corrosion failure preemption capability. In other words, the produced inspection scope would not be able to identify all the existing high-risk areas or locations due to an incomplete or inadequate usage of input data.

To remedy the situation and render a partial risk-based scope more or fully risk-based, one has to use all the available and reliable input data types to more accurately determine the associated probabilities of failures due to corrosion. The ensuing risk values and inspection intervals are, accordingly, more accurate. The outcome is an inspection scope that is fully risk-based and possesses corrosion failure pre-emption capabilities that have been enhanced significantly. Figure 1 lists the various data types that could be used to better and more accurately determine the probability component of a risk value.

Need a roadmap to corrosion management? Learn about IMPACT PLUS, from the NACE International Institute.

Source: “Corrosion Management and Risk-Based Inspection,” by Ali Morshed, consultant corrosion engineer and author, London, United Kingdom. Originally appeared on materialsperformance.com

FREE DOWNLOADS

White Paper: An Action Plan for Reducing Pipeline Failures, Costs with Corrosion in the Water Sector

Special Report: The Future of Corrosion Control, Insights from the Experts

Get Updates

Featured Articles

Categories

- 2024 Olympics (1)

- 2024 Water Resource Development Act (1)

- Abrasive Blasting (1)

- Advanced coating materials (9)

- advanced coatings (1)

- Advanced Corrosion Control in Oil and Gas Industry (2)

- Advocacy (3)

- AI (2)

- Aircraft (1)

- Alkanization (1)

- AMPP (4)

- AMPP Annual Conference + Expo (5)

- ampp awards (1)

- ampp certification (2)

- Ampp Chapters (1)

- AMPP conference (1)

- AMPP logo (1)

- Ampp Membership (2)

- Ampp Standards (3)

- ampp training (2)

- Amusement parks (4)

- Architectural (1)

- Architectural Coatings (2)

- argonne national laboratory (1)

- Artificial Intelligence (1)

- Asset integrity (12)

- Asset maintenance (3)

- Asset Protection (1)

- awards (3)

- B2B Marketing (1)

- Bim Software (1)

- Biodeterioration of materials (5)

- Biofouling (4)

- Blasting (1)

- Bridges (4)

- career advancement (3)

- career development (2)

- cathodic protection (2)

- Cathodic Protection-CP (16)

- Ceramic epoxies (1)

- Certification (3)

- certification study guide (1)

- Chemical Injection (1)

- CIP (1)

- Civil Engineering (1)

- clean energy (1)

- Coating inspector (2)

- coating inspector job roles (1)

- Coating inspector jobs (2)

- Coating inspector program (2)

- Coatings (18)

- Coatings Application (3)

- coatings certification (1)

- Coatings failures (2)

- Coatings Industry (2)

- coatings inspection (1)

- Coatings inspector (2)

- Coatings measurement and inspection (9)

- coatings project management (1)

- Coatings Systems (1)

- Cold stress (1)

- Concrete (13)

- Concrete corrosion (1)

- concrete cracking (1)

- Conference and Events (2)

- Corrosion (26)

- Corrosion Basics (5)

- corrosion certification (1)

- Corrosion Control (17)

- Corrosion Control and Management (23)

- Corrosion detection (1)

- corrosion engineering (1)

- Corrosion Essentials (20)

- Corrosion Inspection (1)

- Corrosion Management (1)

- Corrosion Meaning (1)

- corrosion mitigation (1)

- corrosion of steel (1)

- corrosion policy (1)

- Corrosion Prevention (13)

- corrosion resistance (1)

- corrosion resources (1)

- Corrosion Under Insulation (2)

- cost of corrosion (1)

- Crevice Corrosion (1)

- Cui (2)

- Data Monitoring (1)

- decarbonization (1)

- defense infrastructure (1)

- Department of Defense (4)

- Deposition corrosion (1)

- Dissimilar Metal Corrosion (1)

- Dissolved gases (1)

- DoD (3)

- Education (2)

- EMERG (1)

- Energy industry (9)

- entertainment industry (1)

- Epoxy (3)

- exam preparation (1)

- FBE Application (1)

- FBE Inspection (1)

- Fireproofing (1)

- Flexible coatings (2)

- Flint, Michigan (1)

- Fluoropolymer coating (3)

- Forms of Corrosion (4)

- Freshwater salinization (1)

- Fusion-bonded epoxy (1)

- Galvanic (1)

- Galvanic Corrosion (4)

- General Corrosion (4)

- General Tips (1)

- Global supply chain resilience (1)

- glossary (1)

- Hand tools (1)

- honoree night (1)

- Industrial Application (3)

- Industrial Safety (3)

- Industry Best Practices (1)

- Industry Standards (2)

- Infrared Thermography (1)

- infrastructure (4)

- Infrastructure Durability (1)

- Inspection (1)

- integrity management (1)

- Intergranular Corrosion (1)

- International Maritime Organization (IMO) (1)

- Intumescent Coatings (1)

- key note speaker (1)

- leader (1)

- Machine Learning (2)

- Maintenance (2)

- Maintenance Best Practices (1)

- Maritime Coatings (11)

- Maritime industry (12)

- Maritime infrastructure (1)

- Master Painters Institute (2)

- material protection (1)

- materials performance (1)

- materials science (1)

- Membership (2)

- Membership Benefits (2)

- Michio Kaku (1)

- Microbiological forms (1)

- Microbiologically influenced corrosion-MIC (11)

- Military (2)

- Mineral constituents (1)

- MnDOT (1)

- MPI (3)

- mpi awards (1)

- mpi champion awards (1)

- mpi training (1)

- MPI Update (1)

- MR21506-2025 (1)

- National Defense Authorization Act (1)

- national security (1)

- Naval readiness (1)

- Navy (1)

- nickel-based alloys (1)

- Non-Destructive Testing (1)

- nuclear (1)

- nuclear Materials (1)

- nuclear reactor technology (1)

- Oil and Gas (2)

- Oil Fields (1)

- Organic matter (1)

- Oxgen (1)

- Paint and Protective coatings (32)

- Paint specification (1)

- pcs certification (1)

- Personal Protective Equipment (3)

- Petrochemical Plant Fireproofing Methods (1)

- Petrochemical Plants (1)

- Pipeline (2)

- Pitting Corrosion (2)

- Pitting Detection (1)

- Polymer-Based Coatings (1)

- Power plant (1)

- Power tools (1)

- PPE (3)

- Print Advertising (1)

- Print Marketing Strategy (1)

- professional certification (2)

- professional development (1)

- Protecting oceans (1)

- Protective Coatings (7)

- protective coatings industry (1)

- protective coatings specialist (1)

- quality assurance (1)

- radiation-resistant materials (1)

- Real-Time Corrosion Monitoring in Oil Fields (1)

- Rebar Corrosion (2)

- rectifier (1)

- Reliability (1)

- Remote monitoring and drones (4)

- Repaint (1)

- Restoration (1)

- ride maintenance (1)

- Risk-Based Inspection (1)

- Road deicers (1)

- Roads and bridges (1)

- Roller coaster (1)

- Rust (1)

- sacrificial anodes (1)

- Safety (5)

- Safety Standards (3)

- Salt pollution (1)

- Sensors (1)

- service awards (2)

- Ship Coatings (9)

- Shiptanks (1)

- Solvent-free coatings (1)

- Standards (10)

- Standards Committees (2)

- Steel (8)

- Steel Reinforcement (2)

- Stress Corrosion Cracking (1)

- Structural Steel (1)

- study tips (1)

- Surface Preparation (13)

- Sustainability (2)

- Sustainability and corrosion (7)

- terminology (1)

- Tools (1)

- Turbine (1)

- Types of Corrosion (1)

- Ultrasonic Testing (1)

- Uniform Corrosion (1)

- us army core of engineers (1)

- Wastewater Systems (1)

- Water crisis (1)

- Water pipe corrosion (1)

- Water quality (1)

- Water tank coatings (5)

- Water/treatment infrastructure (20)

- Waterway salinity (1)

- What Is Corrosion (1)

- Workforce development (1)

- WRDA (1)